– SUPPLIER KEYNOTES –

Vescio Threading is a 58-man machine shop located in Santa Fe Springs, California with a smaller division in Mexico. We support complex machining for the medical, automotive, and commercial industries, but the bulk of our output consists of Aerospace and Defense parts. Recently, Vescio teamed with SEA to transform the company using SEA’s Lean Enterprise System. Vescio’s challenge is to reduce lead times and improve delivery faced with a very high-mix, low-volume customer demand. As a result, our major goals include reducing overall setup times for all of our machines by 30% and reducing lead-time by 70% for over 100 of our different parts.

During a recent Kaizen Event, Vescio Threading established its first Flow Cell, with astonishing results! The lead time within the cell was reduced from seven weeks to two weeks, meeting our goal of 70% reduction in one single event. We plan on building five more cells by mid 2010 to expand on winning strategy, with continuing activities for leadership, workforce, and operational improvements scheduled throughout the remainder of 2009 and 2010.

TSI Plastics has been servicing the Aerospace & Defense Industries since 1959 as a contract manufacturer of custom fabricated parts and assemblies. TSI specializes in precision CNC machining & turning, die cutting, injection & compression molding, rotational molding & thermoforming of plastics for a broad range of industries and applications across the United States. TSI is AS 9100 certified and pursuing SEA Certification to continually improve value to the customer.

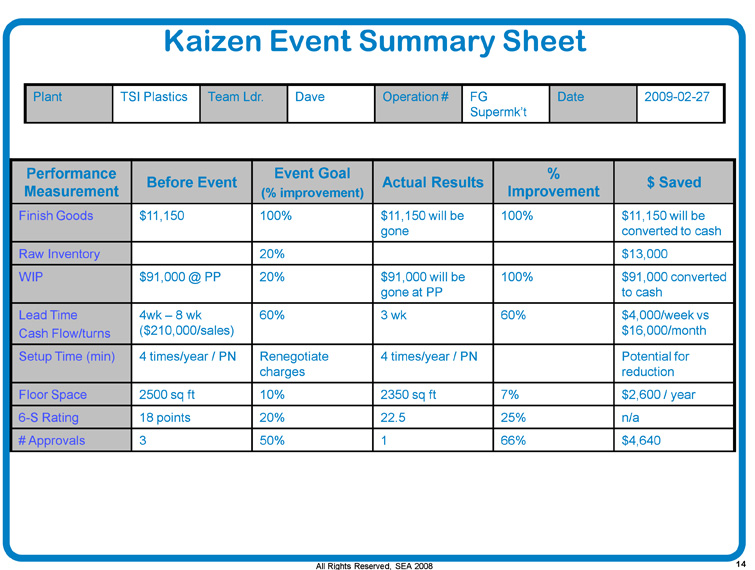

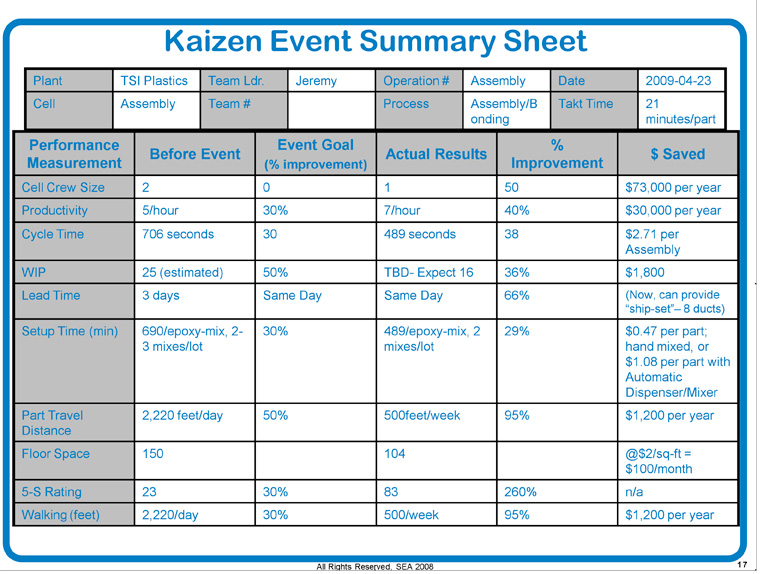

Below are two summaries on improvements that TSI has achieved to save cost and increase flexibility to our customers. Click on thumbnail to enlarge.

MTO raw material supermarket. Showing a 100% reduction in F/G inventory while also helping reduce WIP by $91,000 for this family of parts. Reducing lead-time from 4-6 weeks to 3. This is a huge win for us in reducing the amount of cash we have tied up in production. We are continuing this Kaizen into other families of parts by the end of 3rd quarter this year.

Assembly cell that produces Aerospace Ducting. Showing a 40% increase in productivity, cycle time reduction of 38% and a lead-time reduction from 3 days to 1. This has given us more flexibility to use our man-hours on other jobs in the shop.

– ABOUT SEA –

Did you know…?

SEA is the non-profit alliance of leading aerospace and defense primes and tier-one contractors and leading sub-tier suppliers dedicated to transforming the U.S. supply chain. SEA helps suppliers improve performance, expand capabilities, and collaborate to produce breakthrough, integrated supply chain solutions.

SEA member companies include The Boeing Company, Esterline Corporation, United Technologies, Inc, Parker Aerospace, Rockwell Collins, Honeywell Aerospace, Dresser- Rand, Roberts Tool Company, Photo Etch Company, and DRS Technologies.

SEA partners and alliances include Society of Manufacturing Engineers (SME), National Defense Industrial Association (NDIA), International Aerospace Quality Group (IAQG), Society of British Aerospace Companies (SBAC), and California Space Authority.

Contact Information

For further information and answers to your questions about SEA, please contact:

Headquarters: 2062 Business Center Drive, Suite 225, Irvine, CA 92612

SEA Website: Click here

Main telephone: (949) 476-1144 Ext 339

Executive Director: Mickey Wiebe, Ext 307 Email

Director, Operations: Hilda Pacheco-Taylor, Ext 316 Email

Director, Small Business: David Blanco Ext 334 Email

Director, Outreach: Kimberly Hawkins Ext 332 Email

Director, Sponsorships: Robert Crosby Ext 315 Email

Other Important Links

SEA 2009 Calendar

SEA Roadmap

SEA Certification

SEA Sponsorship Opportunities

What’s New on the SEA Website?

Miss some important news? Here are the most recent additions to the SEA Website:

Check out our new EVENTS tab Click here

Where you can access the following information:

CEO Conferences* - for everyone - Suppliers share their success stories and collaborate on integrated supply chain projects

Supplier Site Visits - for non-members - Non-SEA suppliers visit benchmark sites and determine how best to participate in SEA

Process Owner Forums** - for members only - Process Owners study best practices and compare notes on implementation of the SEA LES

Webcasts - for members only - Members learn how to prepare a quarterly report, how to implement the roadmap, and how to prepare for SEA certification.

Benchmark Site Visits - for members only - Members visit benchmark supplier sites and share information

Certification Workshops* - for everyone - Members and Qualified Associates learn to implement the SEA Lean Enterprise System

*fees apply

** subscription required

Not a SEA member? JOIN NOW!

– UPCOMING EVENTS –

Supplier CEO Conference and Reception September 9 & 10, 2009

Event Chair: SEA

Event Location: Radisson Hotel Newport Beach, CA

Event Page: Click hereThis conference, appropriately titled: “Navigating the Perfect Storm, What’s Process Got to do With it?” will be exploring the role process management plays in navigating today’s tough economic environment. Space is limited and you won’t want to miss the famous SEA hospitality, the opportunity to collaborate with your customers and learn from both customers and suppliers’ experience in navigating the storm.

- Supplier Keynotes – attendees will hear from over a dozen CEO speakers who have followed the SEA roadmap and are growing their business and making plenty of money.

- Customer Keynotes – attendees will also hear from customers about what is changing and what they are looking for in today’s changing business environment.

- Industry Benchmarks – An automotive supplier who is moving into aerospace with 100% on-time delivery and 0 PPM quality.

SEA Leader Workshop

October 19 - 23, 2009

Guide your company on the journey to continuous improvement using the Supplier Excellence Alliance (SEA) Lean Enterprise System – the continuous improvement system designed by and for the aerospace and defense industry. In this in-depth, 5-day workshop, you’ll gain a full understanding of the SEA Lean Enterprise System (LES), the SEA Roadmap, and how to prepare your company for the SEA Certification. Click Here to Register

– SAVE THE DATE! –

Aerospace & Defense Supply Chain Awards Conference

November 10 & 11, 2009

Reception, Conference and Awards Dinner

Event Location: Indian Wells, CA

Event Page: Click here

SPONSORSHIP OPPORTUNITIES – CLICK HERE

Aerospace National Registration Program

There is nothing worse than being one of the best suppliers when nobody knows how to find you! SEA is the joint program office for the aerospace and defense supply chain conversion. For six years we’ve been helping suppliers to accelerate performance improvement and gain increased visibility with their customers. If your company is an aerospace or defense supplier, SEA can accept your registration. Registration is a two-step process.

- Go to the SEA website and register online at: http://seaonline.org/Join/Reg_AeroNatProgram.htm

- Answer the SEA email and send in a copy of your last purchase order.

Once SEA has verified your company’s status as a supplier for the aerospace and defense industry, we will complete the registration. Once your registration is complete, you will begin to receive correspondence from SEA updating you on information relating to the conversion effort. You will be invited to SEA conferences and provided a 10% discount. Your company and contact information will appear on the SEA website and on a SEA directory used by prime and tier one members.

Thank you for helping with the National Registration Drive.

Please forward this registration link to your suppliers!Not a SEA member? JOIN NOW!

– NEWSLINE –

New Industry Practice Leader

Elisabeth Gegner is the Industry Practice Leader for Leadership and Culture at the Supplier Excellence Alliance. In this role, she helps clients develop and successfully implement their continuous improvement strategy, supports and coaches SEA’s Leadership and Culture Consultants, as well as develops materials to support our clients in their transformation journey.

With over 18 years of experience in the fields of strategy, leadership, culture and business transformation, she helps organizations focus and execute on their most important priorities.

Companies that achieved SEA Certification

TA Aerospace, located in Valencia, CA (formerly TA Mfg.) is an industry leader in engineered elastomers and aerospace clamping to the aircraft market.

Through the development of aerospace clamping solutions, Kirkhill-TA has become an industry leader in elastomer technology. Kirkhill-TA’s high temperature elastomer compounds continually set new standards for aerospace silicones. Products include aerodynamic, firewall, high temperature, hatch, door, window, and EMI seals together with other custom and standard shapes.

Geater Machining and Manufacturing Co.

(GMM), located in Independence, Iowa, is a custom precision sheet metal fabrication and machining company. GMM was founded in 1962 and specializes in the production of precision sheet metal and machined components and assemblies for electronics and avionics. GMM serves aerospace, electronics and other high tech industries.

Nominations are now open for the 2009 Aerospace and Defense Supply Chain Awards Click here

Nominations are open to suppliers whether members of SEA or not. You may nominate your own company. Companies nominated must submit a completed application by the application deadline.

SEA announces its new Supplier Registry Click here

SEA Suppliers are distinguishing themselves by accelerating their improvement effort. When they first begin as “Members” they are educating themselves in order to choose the best path to SEA Roadmap implementation. Those who have chosen a path begin to invest, and successfully submitting their quarterly report for review by a SEA examiner qualifies them for the “Engaged” status. Those suppliers who continue their efforts achieve SEA Certification Stages 1-3. SEA Certified Suppliers are setting the bar for the Aerospace & Defense Industry.