Dear SEA Member - February 26, 2013

PROCESS MATURITY FOR LEADERS

Why is it that every supplier CEO we talk to after looking at the SEA Roadmap says, “Yeah, we do that.”? Was everyone already doing the roadmap processes before we started in 2002? Did every supplier have highly mature processes already? And if so, why was SEA formed in the first place?

Back in 2002, the founders of SEA were interested in accelerating supplier performance. In fact, the first mission statement drafted by the board said exactly that, “Accelerating Supplier Performance.” We talked them into changing to “Accelerating Supply Chain Performance” because we recognized that it would not help to always have the finger pointing at suppliers as the culprits on supply chain performance issues. If the supply chain is going to improve it’s going to be the result of collaboration across the entire supply chain, not just what a supplier can do within their own four walls to effect change.

But it was also not accurate to say that suppliers didn’t have some work to do. OTDs of less than 90%, quality ratings of over 20,000 PPM, and lead times of 12-16 weeks told us that we were never going to survive in the face of the moving production lines that were coming from our customers. These moving production lines now demand 100% OTD, 100% quality, and very low lead time across the entire supply chain. Our customers can’t be successful without this support and unfortunately the way we have done business in the past will cost too much to achieve these levels of performance.

But do leaders really understand the role of process maturity in avoiding the costs of giving customers the performance they want?

THE FIRST ROADMAP

The first roadmap had 32 processes – the result of collaboration between our customers and our suppliers. Our customers saw so many issues with suppliers that they just couldn’t stop listing off all the processes that were missing or performed poorly.

SEA staff spent some time with some of the working groups at the time for AS9100 and the Supply Chain Handbook developed by AAQG. Their plans were very sophisticated and included processes that were problems for our customers but not necessarily “core” to how a supplier does business.

Today’s roadmap has been refined to 15 processes – the experience gained by suppliers allowed us to combine and consolidate processes just as the Baldrige Criteria has developed over a 20-year span. A list of the roadmap processes is attached to this report as reference.

But the more the roadmap was simplified the more CEOs who looked at it would say, “We do all of that – maybe not so well, but we already do that.”

The idea of process maturity seems to be escaping almost everyone in the industry.

Nobody said that we weren’t doing these things – they simply said we were not doing them well.

THE FIRST PILOT

The first pilot of the roadmap was held with about 30 suppliers in 2003-4. We asked suppliers to rate their processes 1-5 using the Process Maturity Model as their guide. Most suppliers were honest and rated their processes at 0 or 1 – either non-existent or maturity so low that they couldn’t really confirm that they were being followed at all.

Here are the maturity levels for reference:

0 = The process does not meet any of these requirements

1 = The process addresses most requirements and has a process owner and value stream map

2 = The process is documented to the work instruction level for all major steps in the value stream map

3 = The process is standardized and a certified trainer has trained and certified each appropriate person

4 = The process is under control and is measured and analyzed using data

5 = The process shows positive trends of improvement over time and compares favorably with world class benchmarks

The first companies to take on the task of bringing all of their critical processes to level 3 maturity were pioneers – their owners and leaders had to move into uncharted territory. These companies were mostly “job shops” who had been manned by 2 or 3 generations of the same family – 2 or 3 generations who had done things the same way and passed them down for many years.

Of course ISO9000 had taught people the basics of process maturity but during those times the adoption of ISO was mainly seen as a compliance issue – “you must go through this to get orders from your customer.”

Nobody realized that on the other side of process maturity was a sizable pot of gold in reduced costs, improved performance, increased quality, and the big one, CUSTOMER PREFERENCE. It’s hard to quantify the last one. Customer Preference brings you more orders and more business without incremental cost. Capturing more business without the incremental cost of sales. And the impact of more volume using the same facilities, equipment, and people… How do you quantify that? Only those who have been there know how big that really is.

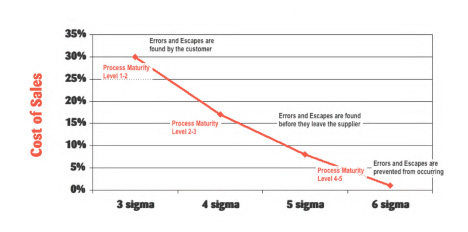

But what we do know is that the Cost of Quality “COQ” is as much as 30% of sales. And when you begin to seriously take out the COQ, revenue drops to the bottom line that can seriously double of triple your net profit. And as you do that, CUSTOMER PREFERENCE comes into play. No big surprise I hope that our customers like suppliers who are predictable, and perform well every single day without breaking a sweat.

When you’re running around putting out fires because nothing is a mature process, you not going to impress anyone. And therefore you’re not going to be competitive, you’re going to get the jobs nobody wants, or you’ll price it so low that you won’t make a dime. If you’ve known your customer for a long time they may give you the “pity jobs” but the “plums” will go to the guys who “get it.”

So is CUSTOMER PREFERENCE worth a lot of money? ABSOLUTELY – you can’t count how much it’s worth. So the chart above only shows the numbers on COQ, but what you get in incremental business from “growing up” is the biggest gain of all.

GROWING UP AS A SUPPLIER

So why be borderline disrespectful and imply that your company maybe hasn’t grown up? I’m taking a risk. I don’t want to offend you. Just get your attention. Growing Up means developing processes that work right every single time – from the front office to the loading dock, every single employee knows how to mature a process, how to follow best practices that have been documented, and has the discipline and skills to follow them.

It’s not a quick fix or even something that can be done overnight, but it is something that can be done consistently for a year with massive results and more the second, third, and so on.

Our customers recognize serious suppliers. They know it when they see it. When you have process owners and master trainers for each of your most customer-critical processes, your customer sees a commitment to excellence – even if you haven’t arrived, a commitment to excellence shows that you both agree on where you need to be – 100% on-time and zero PPM and anything less is just a temporary condition to be remedied with more time.

HOW THIS WORK HAS CHANGED ME

I have undergone my own transformation after 10 years of doing this work. I never realized how big an impact this would have on me personally.

First, I came to realize how important it is to have small family-owned businesses in the US and how important it is that we do everything possible to have our manufacturing businesses thrive and become more competitive on a worldwide basis. I can honestly say that I feel this one to my bones.

Second, I came to realize that even though it might be a matter of survival, some people just don’t want to change. And the biggest issue was the fact that I needed to change how I was looking at the problem myself before I could ask anyone else to change.

I remember my first Blackberry – I think it was a gift – and I immediately thought to myself, “I’m not going to use that. I don’t want to look like one of these yuppies walking into walls while they text on their ‘crackberry’.” Besides, I had a great system going with my Cadillac – a little black book with pages and a calendar in it. I could teach a course on how to think like a dinosaur.

But I worked on it and mastered it and the adoption that early moved me ahead of my peers very quickly because I gained capabilities they would never have – capabilities they didn’t want to have.

So eventually I came to realize that it wasn’t about coming up with the perfect roadmap or training methodology – it was going to be about changing minds. I was watching a movie one night called “Dune” and the hero yelled to someone “The sleeper has awakened!” in a very loud voice. I thought, “Well that certainly woke me up.”

But beyond that I came to realize that the industry has been operating one way for so long, and supplier companies have operated one way for so long, that our leaders are essentially “asleep” and missing the wake up call. Sure there’s a dance going on, but the dancers have danced it so long they can do it in their sleep.

During this past 10 years I developed sleep apnea without realizing it. One day I fell asleep at the wheel but not really asleep, just kind of dreamy as I watched everything going on including driving my car off the road into a set of very big water mains that flipped my car and totaled it. Good thing there was nobody on the road and very fortunate I got out alive.

But I realize that being asleep isn’t always as we might imagine. A few times I’ve run into people who walk and talk almost normally while they are sleep-walking. I’ve come to realize that running a company has some similarities. You almost have to force yourself to do something different – to get out of the routine of fighting fires, working long hours, dealing with problems, and so on.

The last thing I learned is that our customers know almost nothing about how to collaborate and motivate excellence. They threaten, they hold out a carrot on a stick, they set goals and limits – but almost all of that is fruitless because they really believe deep down that it is an adversarial situation.

And why not? Our customers aren’t psychologists – they’re not trained in running a business and 99% of the time they have never owned, managed, or even studied a small company. There is no reason to expect that a purchasing agent or buyer or supplier development or quality rep knows anything about what it takes for you to improve at all. And further they shouldn’t have to. You should be driving them, not they driving you.

Therefore when you are not performing, they will ask you to do things that long term will put you out of business. And it’s because you didn’t do the right things before it got to that point that you’re being asked to do the wrong things now.

I have watched our customers turn a full cycle of the “crank” of supply chain performance over the past 10 years. In 2000, every OEM was adding supplier development resources like crazy. Boeing IDS reportedly had 800 people on the street working with suppliers to improve performance in 2002. By 2003, they were developing integrating supply chains with suppliers performing to MIN-MAX, or Kan-Ban, JIT, delivering Point of Use, or some form of lean supply chain methodology.

Today Boeing is out of the supplier development business. According to them, if you cannot perform and get yourself right with what they need, they are not in the business of fixing that. Same for all the major players. Supplier development among the OEMs is over.

And I think that’s good because it wasn’t working. Not everything of course, but the massive number of people going out to do Kaizens with suppliers wasn’t working. The interventions without management involvement and commitment to excellence wasn’t working. The force-feeding of lean methods was not causing us to achieve 100% on-time and zero PPM performance. You can’t “push a rope,” as they say. The leader has to decide.

When your customer is screaming, “Get Lean!!!” and your employees are screaming, “Get lean!!!” and your consultant is screaming, “Get lean,” it’s just like standing on the diving board with everyone already in the pool yelling, “Jump!!!” and the more they yell the more you get convinced that you don’t wanna do it. Getting lean and improving performance – committing to excellence is something the leader has to do.

I have seen leaders decide to commit to excellence and I have seen these leaders transform their companies. But I have never caused anyone to do that – at least not that I know of. Rather I have had the privilege and the honor to meet people who did that.

And you certainly know them when you see them.

Many thanks to all the leaders who have changed my mind about what it takes to do this and lighted the path for many others to follow.

SEA Processes

1.0 Leadership & Culture

1.1.1 Strategic Planning Process – How do your senior leaders accomplish strategic planning? What are the key process steps and who are the participants? How do you ensure that the process addresses strengths, weaknesses, opportunities, and threats; major shifts in technology, markets, and competition? What are your key strategic goals, measureable targets, and timetables? How are goals and metrics deployed throughout the organization?

1.1.2 Leadership Communication Process – How do senior leaders communicate and reinforce company direction and expectations (vision, goals, mission, and values) to all employees, customers, and key suppliers/partners? What are the key process steps and who are the participants? How do senior leaders encourage frank, two-way communication throughout the organization? How do senior leaders create and re-enforce a high-performance work culture that embraces standard work, process maturity, and lean production techniques? How do senior leaders involve themselves in reward and recognition that re-enforces a high-performance work culture?

1.1.3 Organizational Performance Review Process - How do senior leaders review organizational performance to assess organizational success, competitive performance, and progress relative to strategic goals and action plans? How do senior leaders select, organize, and assess key performance metrics and measureable goals? How do senior leaders translate organizational performance review findings into priorities for continuous improvement?

1.1.4 Continuous Improvement Management Process – How does your organization select improvement priorities and review progress on improvement initiatives? How are process owners, master trainers, and strategic champions included in this process? How are improvement projects and teams selected and given direction? How is a standard problem-solving model deployed throughout the organization? How are recognition and sharing of key learning accomplished? How are process improvement ideas solicited, reviewed, approved, and implemented? How is a high level of workforce participation ensured? How are improvement suggestions recognized? How are suggestions made visible in work areas?

1.1.5 Workforce Development Process – How do senior leaders evaluate the need for workforce development and select topics for each level and function? How does the selection of training topics integrate with strategic goals and process improvement needs? How is the workforce-training plan prepared and monitored? How does your organization ensure continuous learning from improvement projects, customers, and suppliers? How does your organization integrate benchmarking into the learning process? How does your organization integrate such learning into on-going employee education, training, and development?

1.2.1 Supply Chain Integration Process – How do senior leaders select supply chain improvement projects? How does your organization integrate its customers and suppliers into its improvement strategies? How do you qualify suppliers in quality, delivery and ability to respond to pull signals? How do you integrate suppliers into your lean strategies such as in supplier-managed inventory, min-max, consumption-based ordering, pull signals? How does your organization make use of teaming agreements to drive alliances that improvement supply chain performance?

1.3.1 New Product Startup Process – How does your organization contribute to the immediate success of customer startup operations including first article and early production efforts? How are processes like Advanced Product Quality Planning “APQP” and Production Preparation Process “3P” used to pro-actively ensure value for customers? How are customers needs for reduced lead time and high levels of initial quality considered in the startup process?

2.0 Workforce Development

2.1.1 Job Skills & Cross-Training Certification Process - How is job skills training and certification accomplished? How does your organization ensure that processes selected are linked to key priorities for improvement? How is cross-training accomplished? How is the team of master trainers maintained and expanded? How is the training and cross-training program reviewed?

2.2.1 Work Area Continuous Improvement Process – How is continuous improvement supported in all work areas? How are improvement projects linked to work area goals? How does the work area integrate continuous improvement into their daily operations? How are problem-solving and corrective action methods standardized in all workgroup processes? How are work areas and cells reviewed by senior management? How are statistical methods integrated into the standard work for appropriate managed processes? How are process control plans developed and implemented? How are statistical methods reviewed and their application improved?

3.0 Operational Excellence

3.1.1 Kaizen Process – How does your organization set and review priorities for Kaizen events? How are Kaizen events conducted? How is recognition for team members provided and are senior managers and the workforce involved? How are lessons learned shared with others who can benefit? How are process improvements documented and deployed to others using the same or similar processes? How are internal Kaizen leaders developed and deployed? How are goals set for Kaizen leadership and how is progress monitored?

3.1.2 6S Visual Workplace Process – How does your organization ensure effective deployment of 6S Visual Workplace strategies for workplace organization? How are the 6S status, process flow, production status, employee training status, and continuous improvement effort clearly displayed and visible in the office and factory floor? How does your organization ensure that work areas are kept consistently free of dirt and clutter? How are improvements reviewed and recognized?

3.1.3 Quick Changeover/SMED Process – How does your organization continually reduce changeover and setup times? How are changeover and setup times tracked and displayed on the factory floor? Have machine operators been formally trained in SMED methods? How is progress reviewed and recognized? What metrics are monitored?

3.2.1 Material Management Process – How does your organization ensure the effectiveness of material management processes in support of its lean and flow manufacturing objectives? How does your organization maintain a high level of inventory accuracy? How do you maintain a high level of 6S in material storage areas? How are levels of obsolete, slow-moving and expedited material maintained at a minimum? How are material handlers, material planners and supervisors formally trained in material management methods? How does your organization integrate the requirements of a flow-based material process? How are “pull” methods such as material Kanbans, consumption-based ordering and min-max utilized? How are Kanban supermarkets integrated into factory floor operations?

3.2.2 Production Planning Process – How does your organization ensure the effectiveness of production planning processes in support of its lean and flow manufacturing objectives? How often are production requirements updated and communicated to the factory floor? How are production schedules communicated to different work centers? How are pull methods such as FIFO lanes and supermarkets used to replace the need for detailed production schedules? How are production planners trained in production planning methods? How does your organization integrate mixed model cell/line design into its operations throughout the enterprise? How are production and industrial engineers, production managers and supervisors, and material management personnel trained in the lean mixed model line design methods? How are major processes linked and balanced into a continuous flow? How are pull methods such as In Process Kanbans, FIFO lanes and Kanban supermarkets integrated into the production flow? How are operators cross-trained for multiple workstations?

3.2.3 Development Process – How does your organization design and develop new products or services? How are advanced techniques such as Six Sigma, Design of Experiments, Design to Cost, Design for Manufacturability integrated into your operations? How are customers and suppliers integrated into your development process? How is the development process reviewed and improved?

4.0 Business Results

4.1.1 Inventory Turns – What is your organization’s monthly history in inventory turns?

4.1.2 Sales/Employee – What is your organization’s monthly history in sales per employee?

4.1.3 On-Time Delivery – What is your organization’s monthly history in on-time delivery?

4.1.4 Parts per Million – What is the organization’s monthly history in parts per million defects?

4.3.1 Process Maturity 3 and above – What is the organization’s quarterly history in processes achieving Level 3 process maturity or above?

4.3.2 Quick Ratio – What is the organization’s monthly history for quick ratio? |

Michael Beason

Chairman, CEO

Supplier Excellence Alliance |