Dear Performing Suppliers - September 20, 2010

Documenting your roadmap processes will not improve your operations. It can’t make your needles move

on OTD, PPM, etc.

That’s why documenting your processes should not hold up your progress in actually making improvements to your operations. Sure implementing the roadmap ensures long-term sustainability and that’s important, but let’s not use it as an excuse for delaying improvements.

I can tell process owners how to get their process documentation complete in 4 pages and less than two

weeks. But even if it takes longer, we should not be waiting to implement improvement.

Don’t use the fact that your processes are not fully documented yet to delay making actual improvements!

Let’s consider 3.1.1 Kaizen Process. We certainly want to stabilize our process and develop a documented

process for doing this work. But we can’t wait six months or event one month to accomplish that. If you

have selected a value stream and defined which processes need to be managed and improved, you need

to get to work scheduling a kaizen event. There’s no time. We need to get 7 of 12 months showing

improvement over baseline. That’s not a hard thing to achieve, but it rarely happens if you are sitting on

projects that have 12 months to document the process!

As well, let’s consider 3.1.2 6S Process. We’re bringing customers through our shops frequently and these

visits are great opportunities to blow their socks off. From a SEA perspective, we want every customer who visits a SEA supplier to come away thinking, “Wow – do those guys have their stuff together!?”

Now I know that you’ve had site visits in the past where they said that. But don’t rest on your laurels. The bar is going up every day. If you are unfortunate enough to be the next supplier to be site-visited after a Toyota Plant, you’re not going to look very good no matter what you do. Same with the next special processing supplier to get a visit after Hixson, or the next machining supplier visit after Roberts or W Machine Works. The bar is going up and you can’t sit back and say, “Our site visits will WOW our

customers.”

6S is one of the strongest ways to ensure a great site visit. It’s very visible and that works to your

advantage on a site visit. If you download the materials for the “Preparing for the SEA Site Visit” webcast, you’ll see a white paper and some excellent examples. You don’t need to wait to get your 3.1.2 documentation done to begin. You can’t wait to begin. Every site visit is another opportunity lost if you don’t “WOW!” your visitors. Making sure you have lines and signs in every department, creating a team board at every site visit stop, and putting up samples of work instructions, lists of processes at maturity level 3, and value stream maps – all of these things are a part of a robust 6S program.

Of course we want to get certified as soon as possible and that requires 4 pieces of paper for each of 11

roadmap processes. But we also have to show improvement over time and that takes time so we need to

ensure that improvements are being made constantly. That means Kaizen and 6S and Changeover

projects need to get defined in your Management Planning Activity and then executed on a quick timeline.

If you ask a GM from a Toyota Plant to come in and look at your shop and give you feedback, I’ll tell you

what he’ll do every time. He’ll walk directly into your shop, look around at batches of materials, ask about

changeover times on each workstation, and walk back to you inside of 10 minutes and say, “Set-up time.

Work on set-up time,” and then he’ll leave. To them, it’s obvious. To us, it hides out in an ocean of waste.

But they know that in order to improve operations you have to speed up materials and make it harder for

everyone to perform at higher quantities. Changeover is the key to getting this cycle started.

There are mountains of cash hiding out in most of our businesses. We say we don’t have any cash but

that’s like the popular story about boiling a frog. If you throw him into the water that’s already boiling he

jumps out. But if you put him in lukewarm water and slowly bring it to a boil, he won’t know he has a

problem until it’s too late and he can’t get out.

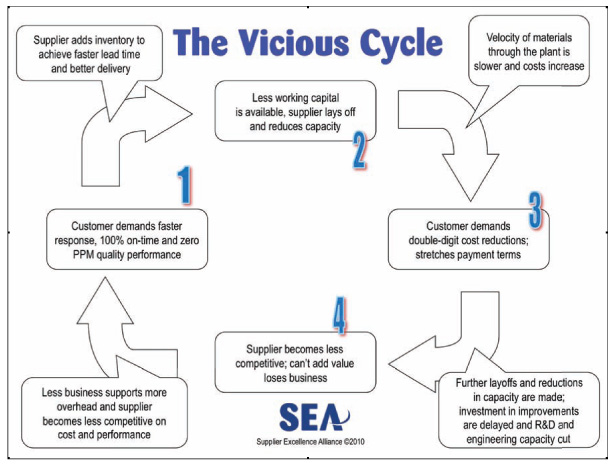

When you’re drowning in an ocean of inventory, it’s hard to recognize that if you wait to act, it’s going to get harder and harder to get out. The more pressure to perform, the more inventory you add, the less cash you have, and then of course they pay you slower, and pretty soon you have no choice but to close your doors.

As my father used to say, “Get while the getting is good.” Now is an ideal time to get certified and become one of the leaders of SEA. Our strategy to brand our excellence is working. Customers are very interested in SEA’s approach. It gives them stronger process management in their supply chains and that spells reduced cost while reducing risk.

Please don’t let the SEA LES implementation fall into the bucket that so many improvement projects fall

into – “we’re waiting to get our processes fully documented” and “John’s handling that and he needs

another 9 months to complete it.”

Now a quick word on another topic and then I’ll close. The topic is building internal expertise.

We have a tremendous number of “do-it-yourselfers” or “DIYs” – those who are implementing the SEA LES themselves using internal resources and little or no help from outside consultants or schools. The key to being a successful DIY and there are many examples of successful implementations by DIYs, is to build the internal expertise or bench strength in lean manufacturing.

You can’t improve your operations documenting your processes. SEA is not an exercise in compliance.

You can’t comply and pass the SEA certification audit. You have to build resources and capabilities.

Continuous Improvement Coordinator – you have to have someone who can take the SEA materials and

do a good job of training process owners and master trainers. These two resources are only as good as the training they receive. Most successful DIYs have a general manager, owner, president, or someone with prior lean and training experience. Someone has to take the ball and run with the responsibility of training process owners and master trainers.

Kaizen Leader – a DIY has to have at least one person with extensive experience in leading Kaizen events

to develop new Kaizen Leaders and to oversee Kaizen events. This Kaizen Leader has to provide the

expertise required by the process owners for 3.1.1 Kaizen Process, 3.1.2 6S Process, and 3.1.3

Changeover Process. Someone in this role needs to know how to implement lean solutions such as rapid

changeover, supermarkets and kitting, kanban, flow, takt time, and more.

In spite of this expertise, the management team has to take on the implementation personally. The senior managers needs to learn to speak the new language and they need to know the SEA Roadmap better than anyone else in the business. We can’t let the fact that we have two people “on point” for lean and roadmap implementation make us think we can turn our attention elsewhere.

Building our internal lean bench strength is essential to success.

Here are a few links you may not be familiar with – they’re located on the SEA website.

If you think you know everything about the cost and return for continuous improvement, read this -

http://www.seaonline.org/docs/INVESTINGINIMPROVEMENT.pdf

If you weren’t aware of the SEA webcasts program, look here - http://seaonline.org/Briefings/webcasts.html

If you haven’t seen the supplier registry lately, this is where we send our customers -

http://seaonline.org/Suppliers/index.htm

|

Michael Beason

Chairman, CEO

Supplier Excellence Alliance |